As to heat reduction/reflection

If you have not used like this as example, this comes in sheets and have a sticky backing that works at high temps

Very thin and could be placed on the underside of the floor pan above the exhaust system and also can be wrapped around the pipes

Also helps reduce sounds

View attachment 32319

Where performance is an issue as you know the smallest diameter of the exhaust dictates the total flow volume for the whole exhaust length

With reduced flow and increased back pressure, that also reduces exhaust pulses to pull the exhaust out of the cylinders when exhaust valve opens

That means when that valve closes not all the exhaust has been removed so next time the cylinder fires it is not a clean charge

so not a good burn, which reduces how efficient the air and fuel since dirty exhaust is still in cylinder volume

That reduces performance and fuel mileage

The 2.5" to 2" reducers really hurt the flow and would be better if the mufflers had an inlet and outlet of 2 1/2 inches

Consider like I have, and other newer Corvettes uses 3 inches with no reductions

On the nutty side, I made my exhaust 3 inches from collector with mufflers have 3" in and outlets through muffler tips.

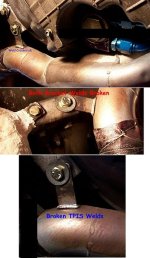

Shown in race mode but for street, 3 inch pipes are installed to tips at the ass end

and the X-pipe design assured no reduction of flow and increases the exhaust pulses to pull exhaust out of cylinders

View attachment 32320