You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bubbling Coolant Header Tank

- Thread starter Andrew

- Start date

Steven Smith

CCCUK Member

Make sure you get a good brand of wheel hub, Timken, SKF or ACDelco. Don't buy cheap otherwise you will be doing them again soon.Thanks clever people-i have all the parts i need now. The car is so ridiculously low that it needs to be done on a pit or ramp. Yesterday it failed its MOT on front ball joints and rear play in the wheels (wobbly)- they said hubs- so onwards and upwards

Front lower ball joints are a press (bearing press) fit, uppers you have to drill out rivets and bolt in new ones. While it's all apart I would do both upper and lowers.

Hello- quick update:- my car is back from the garage having passed its MOT- so thank you to everyone for your help with the ball joints and bearings.

While at the garage the radiator (5.7-L98 C4 base 1989) is said to have failed dramatically from the plastic side jacket. They fitted a new one i gave them with new upper and lower hoses and coolant. They say the sensor on the top right of the rad was destroyed in the blast and needs to be replaced. May i ask what that sensor is called which goes into the rad? The connecting wire to it is currently hanging loose. Please could you guys kindly post a link to what i need on rockauto?

Is it an outside temp sensor? What does it do/prevent?

Even with a new rad; without this sensor the car now runs super hot at over 224°F. It is back disgracing itself publicly by boiling its coolant header tank like the bad old days even with the super cold air temperature today.

Steam was rising from the right headlamp like a giant locomotive causing everyone in the petrol station to fear it was on fire!

It also now stutters when you open the throttle wide open.

Your previous advice to fit the 180deg thermostat is noted- i have the part and will fit over xmas.

While at rockauto online, should l also replace the 2 engine block coolant sensors to get the fans running at a lower temp? (i dont know if the fans work at all)

While at the garage the radiator (5.7-L98 C4 base 1989) is said to have failed dramatically from the plastic side jacket. They fitted a new one i gave them with new upper and lower hoses and coolant. They say the sensor on the top right of the rad was destroyed in the blast and needs to be replaced. May i ask what that sensor is called which goes into the rad? The connecting wire to it is currently hanging loose. Please could you guys kindly post a link to what i need on rockauto?

Is it an outside temp sensor? What does it do/prevent?

| Outside Temperature Sensor |

|

Even with a new rad; without this sensor the car now runs super hot at over 224°F. It is back disgracing itself publicly by boiling its coolant header tank like the bad old days even with the super cold air temperature today.

Steam was rising from the right headlamp like a giant locomotive causing everyone in the petrol station to fear it was on fire!

It also now stutters when you open the throttle wide open.

Your previous advice to fit the 180deg thermostat is noted- i have the part and will fit over xmas.

While at rockauto online, should l also replace the 2 engine block coolant sensors to get the fans running at a lower temp? (i dont know if the fans work at all)

Steven Smith

CCCUK Member

Hello- quick update:- my car is back from the garage having passed its MOT- so thank you to everyone for your help with the ball joints and bearings.

While at the garage the radiator (5.7-L98 C4 base 1989) is said to have failed dramatically from the plastic side jacket. They fitted a new one i gave them with new upper and lower hoses and coolant. They say the sensor on the top right of the rad was destroyed in the blast and needs to be replaced. May i ask what that sensor is called which goes into the rad? The connecting wire to it is currently hanging loose. Please could you guys kindly post a link to what i need on rockauto?

Is it an outside temp sensor? What does it do/prevent?

Outside Temperature Sensor

- 4400 Ohms @ 60 F, 2200 Ohms @ 85 F. Right side of engine, top right corner of radiator

Even with a new rad; without this sensor the car now runs super hot at over 224°F. It is back disgracing itself publicly by boiling its coolant header tank like the bad old days even with the super cold air temperature today.

Steam was rising from the right headlamp like a giant locomotive causing everyone in the petrol station to fear it was on fire!

It also now stutters when you open the throttle wide open.

Your previous advice to fit the 180deg thermostat is noted- i have the part and will fit over xmas.

While at rockauto online, should l also replace the 2 engine block coolant sensors to get the fans running at a lower temp? (i dont know if the fans work at all)

Do you mean this sensor?

If so it a low coolant level sensor I believe.

These engines do run hot, the fans are designed to turn on at 225° F.

I would guess you have an airlock in the cooling system, they can be difficult to bleed the system especially if the garage just filled the header tank with coolant.

My advice would be to jack up the front of the car as high as possible, remove the knock sensor/ sensors and flush the whole coolant system out including the engine block, loads of crud came out of my 86 when I did it !

Fit the new 180° thermostat (that won't make it run any cooler but just get the coolant flowing around quicker) but don't fit the housing.

Refit all hoses and start filling the system with coolant through the thermostat housing with the radiator cap off squeezing the hoses to get the air out, once the engine block is full of coolant refit thermostat housing then top up radiator.

Without fitting radiator cap start engine and let it run up to temperature topping up radiator with coolant as required.

When it has stopped bubbling and engine hot turn it off and let cool, top up radiator once more and refit a new radiator cap (15 psi rated I think).

Lower car to ground and top up expansion tank.

That should sort it out.

I believe you can get sensors that turn on fan earlier or wire in an additional thermostatic control as I have done.

Steven Smith

CCCUK Member

I am not sure how well these work as the ECU turns the fan on and that is set in the "software". You can do it by re writing the ECU but that's beyond me.(in a you tube video i watched the guy used lower temperature replacement engine coolant sensors screwed into the block?)

View attachment 28817

View attachment 28818

The main fan is switched by a relay controlled by the ECU, this has a permanent positive supply and the ECU switches negative to it turning on the fan.

I have fitted an extra thermostatic controller that supplies the negative at whatever temperature I set it at.

The beauty is that if my thermostat fails the ECU will still turn the fan on at 225°F and turning the AC also turns the fan on, win, win in my book.

teamzr1

Supporting vendor

As to temps

1. ECT is mounted in engine, if the coolant temp gauge in dash works correctly then not your issue

2. low coolant sensor would be mounted low and would trip warning on dash if low level

3, I suspect your issue could be the temp sensor for the HVAC

Look at the screen for HVAC and sees if showing the correct outside temp

That is used when using the auto mode of HVAC to determine what mode to go to and in part needs outside temp reading

If I recall that sensor is on right side of radiator

Attached below, I have included a r4 owner's manual and the GM engineering 183 pages PDF

Damn, this forum limits file sizes of attachments so if you do not have the owner's manual that explains HVAC and outside temps

then I would need your email address to email a Cr4 owner's manual

1. ECT is mounted in engine, if the coolant temp gauge in dash works correctly then not your issue

2. low coolant sensor would be mounted low and would trip warning on dash if low level

3, I suspect your issue could be the temp sensor for the HVAC

Look at the screen for HVAC and sees if showing the correct outside temp

That is used when using the auto mode of HVAC to determine what mode to go to and in part needs outside temp reading

If I recall that sensor is on right side of radiator

Attached below, I have included a r4 owner's manual and the GM engineering 183 pages PDF

Damn, this forum limits file sizes of attachments so if you do not have the owner's manual that explains HVAC and outside temps

then I would need your email address to email a Cr4 owner's manual

Attachments

Steven Smith

CCCUK Member

The file has come through, just opened itAs to temps

1. ECT is mounted in engine, if the coolant temp gauge in dash works correctly then not your issue

2. low coolant sensor would be mounted low and would trip warning on dash if low level

3, I suspect your issue could be the temp sensor for the HVAC

Look at the screen for HVAC and sees if showing the correct outside temp

That is used when using the auto mode of HVAC to determine what mode to go to and in part needs outside temp reading

If I recall that sensor is on right side of radiator

Attached below, I have included a r4 owner's manual and the GM engineering 183 pages PDF

Damn, this forum limits file sizes of attachments so if you do not have the owner's manual that explains HVAC and outside temps

then I would need your email address to email a Cr4 owner's manual

teamzr1

Supporting vendor

The file has come through, just opened it

Yes for the GM eng PDF but not for the C4 owner's manual as forum refused due to PDF size

teamzr1

Supporting vendor

I am not sure how well these work as the ECU turns the fan on and that is set in the "software". You can do it by re writing the ECU but that's beyond me.

The main fan is switched by a relay controlled by the ECU, this has a permanent positive supply and the ECU switches negative to it turning on the fan.

I have fitted an extra thermostatic controller that supplies the negative at whatever temperature I set it at.

The beauty is that if my thermostat fails the ECU will still turn the fan on at 225°F and turning the AC also turns the fan on, win, win in my book.

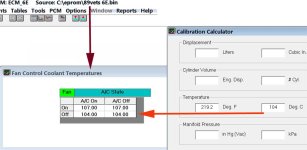

I can change when the coolant fans are commanded on or off, with A/C on or off within the calibration in the ECM

Calibration is stored in an E-prom

If someone in the UK needed custom tuning for OBD-I GM like C4s I can do the tune and email to them

but they need access to a E-prom burner to flash my tune into the E-prom and swap it with the GM one in the ECM

Stock coolant fan settings for a 1989 C4

As you see ECM commanding fan on/off from 104 to 107 C degrees

Too fricking hot and all for damn smog rules in USA back then

I suggest changing Tstat to 170 F deg and then changing tune to work at that lower coolant temps

teamzr1

Supporting vendor

Hello- quick update:- my car is back from the garage having passed its MOT- so thank you to everyone for your help with the ball joints and bearings.

While at the garage the radiator (5.7-L98 C4 base 1989) is said to have failed dramatically from the plastic side jacket. They fitted a new one i gave them with new upper and lower hoses and coolant. They say the sensor on the top right of the rad was destroyed in the blast and needs to be replaced. May i ask what that sensor is called which goes into the rad? The connecting wire to it is currently hanging loose. Please could you guys kindly post a link to what i need on rockauto?

Is it an outside temp sensor? What does it do/prevent?

Outside Temperature Sensor

- 4400 Ohms @ 60 F, 2200 Ohms @ 85 F. Right side of engine, top right corner of radiator

Even with a new rad; without this sensor the car now runs super hot at over 224°F. It is back disgracing itself publicly by boiling its coolant header tank like the bad old days even with the super cold air temperature today.

Steam was rising from the right headlamp like a giant locomotive causing everyone in the petrol station to fear it was on fire!

It also now stutters when you open the throttle wide open.

Your previous advice to fit the 180deg thermostat is noted- i have the part and will fit over xmas.

While at rockauto online, should l also replace the 2 engine block coolant sensors to get the fans running at a lower temp? (i dont know if the fans work at all)

As I mentioned in other post to see if HVAC correctly shows outside temp, if not than that is the sensor you want to replace

But something stinks as to whoever worked on your C4 and caused overheating which caused and cap damage

Maybe they did not purge all air pockets out of cooling system would cause high temps, else

Tsat in engine is bad and stuck closed, or belt from crank to water pump an issue and not turning the coolant pump

If replacing the Tstat, if C4 is driven on cold weather go to a 180 F, rather stock 195 F or

If only driving in like summer weather go with a 170 F degree and engine would run cooler and better

Nest case of course with a 170 ZF deg is have a ECM tune to command fans on at 170 and not fricking 215ish F

Steven Smith

CCCUK Member

What kind of E-Prom burner is required to do that ?I can change when the coolant fans are commanded on or off, with A/C on or off within the calibration in the ECM

Calibration is stored in an E-prom

If someone in the UK needed custom tuning for OBD-I GM like C4s I can do the tune and email to them

but they need access to a E-prom burner to flash my tune into the E-prom and swap it with the GM one in the ECM

Stock coolant fan settings for a 1989 C4

As you see ECM commanding fan on/off from 104 to 107 C degrees

Too fricking hot and all for damn smog rules in USA back then

I suggest changing Tstat to 170 F deg and then changing tune to work at that lower coolant temps

View attachment 28821

teamzr1

Supporting vendor

You can do a search as example on Amazon as several to choose from

Example this one is $60 and can burn/flash into many types of E-proms

GM used through the years for vehicles ECMs,

E-prom sizes of 32, 128, 256 and 512 K bytes so want a burner that can handle different sizes and E-proms that have 24 or 28 pins

There are E-prom tools come with the burner, cable and software that runs on MS-Windows

In the case such as an 1989 C4 the ECM uses a 27C128 E-prom which has 28 pins

This means that E-prom hold 128K bytes of data

Also, may want to get an E-prom eraser to be able to delete data on a used E-proms to allow it to be

burned again with new data

Here is from Amazon, programmers, erasers and E-Proms

Example this one is $60 and can burn/flash into many types of E-proms

GM used through the years for vehicles ECMs,

E-prom sizes of 32, 128, 256 and 512 K bytes so want a burner that can handle different sizes and E-proms that have 24 or 28 pins

There are E-prom tools come with the burner, cable and software that runs on MS-Windows

In the case such as an 1989 C4 the ECM uses a 27C128 E-prom which has 28 pins

This means that E-prom hold 128K bytes of data

Also, may want to get an E-prom eraser to be able to delete data on a used E-proms to allow it to be

burned again with new data

Here is from Amazon, programmers, erasers and E-Proms

teamzr1

Supporting vendor

Example for a 1989 C4 only

What values and tables I can change, and then new tune would be burned into a new or erased E-prom 27C128 K

ECM Switch Parameters

VATS Select, X = Enabled

Normally Open Fan Request Input

Sliding Filter for Airflow, X = Enabled

Open Loop Purge

Single Fire Mode

Dual Air Valve

Cansiter Purge when Output Energized

C.A.R.S. Select (X = Enabled)

Manual/Auto Transmission, X = Manual

4th Gear Switch N.O.

TCC Control, (X = RPM else MPH)

Unlock TCC in Decel Fuel C/O

TCC Locked Highway Spark Enable Check

4th Gear Highway Mode Spark Check

TCC/Shift Light Control (0 = TCC)

No Ref. Pulse Diag. (Error 12)

O2 Sensor Diag. (Error 13)

ECT Sensor High Diag. (Error 14)

ECT Sensor Low Diag. (Error 15)

TPS Sensor High Diag. (Error 21)

TPS Sensor Low Diag. (Error 22)

MAT Sensor Low Diagnostic (Error 23)

Vehicle Speed Diag. (Error 24)

MAT Sensor High Diagnostic (Error 25)

EGR Diagnostic (Error 32)

MAF Sensor High (Error 33)

MAF Sensor Low (Error 34)

MAF Burnoff Diag. (Error 36)

Cylinder Select Diagnostic (Error 41)

EST Monitor Diagnostic (Error 42)

Knock Diagnostic (Error 43)

O2 Sensor Lean Diagnostic (Error 44)

O2 Sensor Rich Diagnostic (Error 45)

VATS Diagnostic (Error 46)

EPROM Diagnostic (Error 51)

Missing CalPack Diagnostic (Error 52)

Over-Voltage Diagnostic (Error 53)

Fuel Pump Voltage Diagnostic (Error 54)

ECM Constants

Initial Spark Advance

Cool Compensation Spark Table Bias

Min RPM for Highway Mode Spark

Load Value to Disable Highway Mode Spark

Min Coolant Temp for Highway Mode Spark

Highway Mode Spark Enable Delay

Spark Advance Added in ALDL Mode

Max Spark Advance

Knock Retard Enable RPM Threhold

Knock Retard Delay Time

Stall Saver Spark Disable RPM Threshold

Fuel Cutoff Speed

Fuel Resume Speed

Fuel Cutoff Engine Speed

Fuel Resume Engine Speed

Injector Flow Rate, Single Fire

Injector Flow Rate, Double Fire

Display Injector Flow Rate

Stochiometeric Air Fuel Ratio

Hot O2 Closed Loop Timer

Warm O2 Closed Loop Timer

Cold O2 Closed Loop Timer

Closed Loop Fuel Enable Coolant Temp.

Minimum Delta TPS For Accel. Enrich.

Min Delta TPS A.E. Async Pulse Width

Minimum Delta LV8 For Accel. Enrich.

Max Accel. Enrich. Async Pulse Width

DFCO Enable RPM Threshold

DFCO Disable RPM Threshold

DFCO Enable Load Threshold

DFCO Disable Load Threshold

Max. RPM Decrease/12.5ms To Stay In DFCO

DFCO Enable TPS Threshold

DFCO Disable Vss Threshold

DFCO Enable Coolant Temp.

Decel Enlean Enable Diff. TPS Threshold

Decel Enlean Enable Diff. Load Threshold

Decel Enlean BPW Factor (Low DRP's)

Decel Enlean BPW Factor (High DRP's)

Min Speed for Highway Mode Fuel

Load Value to Disable Highway Mode Fuel

Min Coolant Temp for Highway Mode Fuel

Highway Mode Fuel Enable Delay

Max Time in Highway Fuel Mode

Minimum BLM value

Maximum BLM value

Min. Coolant Temp for BLM Update

Max. Coolant Temp for BLM Update

BLM - Update Rate

BLM Update Cell Amount

BLM Update - Min Pos. Integrator Error

BLM Update - Min Neg. Integrator Error

Minimum Integrator Value

Maximum Integrator Value

Startup Enrichment Decay Rate

Min Coolant Temp. For High Temp P.E. AFR

Idle Speed Adder in Park/Neutral

Idle Speed Adder A/C On

IAC Startup Park Position

IAC Startup Delay Time

Warm Park IAC Steps Adder - A/C On

IAC Control Deadband RPM Error (in P/N)

IAC Control Deadband RPM Error (Drive)

IAC Learn - Min Coolant Temp

IAC Learn - Max Coolant Temp

Throt. Follower IAC Steps Added in Drive

EGR On, (TPS)

EGR Off, (TPS)

Min. MAT to Enable EGR

MAF High Diagnostic (Error 33) Threshold

TCC Unlock Speed (Low Gears)

TCC Lock Speed (Low Gears)

TCC Unlock Speed (High Gear)

TCC Lock Speed (High Gear)

TCC Unlock Prevention Speed

TCC Enable Coolant Temp. Threshold

Min. Load Limit for TCC Lock, Low Speed

Min. Load Limit for TCC Lock, High Speed

TCC Min Load Limit Hysteresis

TCC Min Load Limit High/Low Speed Thresh

Shift Light Enable Coolant Temp. Thresh.

Shift Light Enable Vehicle Speed Thresh.

Shift Light Enable %TPS Threshold

Shift Light Enable RPM Threshold

Shift Light Disable RPM Threshold

Shift Light Force On RPM Threshold

Shift Light Force On Disable RPM Thresh

Min Canister Purge Duty Cycle (Low TPS)

Canister Purge - Coolant Temp. Enable

Canister Purge - Vehicle Speed Enable

Canister Purge - TPS Enable

Canister Purge - Vehicle Speed Disable

Canister Purge - TPS Disable

AIR Divert Enable Coolant Temp.

AIR Divert O2 mV Rich/Lean Thresh Reduc.

Default MAF Maximum %TPS Value

Default MAF IAC Scale Factor

Minimum Default MAF Value

Number of Cylinders

Tables

ECM Switch Table

ECM Constant Table

Main Spark Advance Vs. RPM Vs. Load

Cool Compensation Spark Vs. Load Vs. Cool. Temp.

Spark Advance In Power Enrich. Vs. RPM

Knock Attack Rate Vs. RPM (Deg/msec)

Knock Recovery Rate Vs. RPM (%/sec)

Maximum Knock Retard Vs RPM In P.E.

Maximum Knock Retard Vs Load, (Not In P. E.)

Highway Mode Spark Advance Vs. Load

Start Up Spark Advance Vs. Coolant Temp.

Startup Spark Advance Decay Step Vs. Cool. Temp.

Startup Spark Advance Decay Delay Vs. Cool. Temp.

Stall Saver Spark Enable RPM Thresholds

%TPS To Enable Power Enrich. Vs RPM (Normal)

%TPS To Enable Power Enrich Vs RPM (Hot)

P. E. %ChangeTo Fuel/Air Ratio Vs Coolant Temp.

P. E. %Change To Fuel/Air Ratio Vs RPM

Open Loop Fuel/Air Ratio %Change Vs.Load

Open Loop Fuel/Air Ratio %Change Vs. Coolant Temp.

Startup Fuel/Air Ratio %Change Vs. Coolant Temp.

Startup Enrich Decay Amount Vs. Startup Cool Temp.

Startup Enrich Decay Delay Vs. Startup Cool Temp.

Highway Mode AFR Vs. Load

Injector Pulse Width Correction vs Battery Voltage

Low Pulse Width Injector Offset Vs. BPW

Accel. Enrich %BPW Factor Vs Async Pulse

No. of Accel Enrich Async Pulses Vs. Coolant Temp.

Accel. Enrich. Async Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Factor Vs. Delta LV8

LV8 Accel Enrich Coolant Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Decay Rate Vs. Coolant Temp.

Crank Fuel Pulse Width Vs. Coolant Temp.

Crank Fuel Pulse Width Multiplier Vs. TPS

Crank Fuel PW Multiplier Vs. Ref. Pulses (1-16)

Crank Fuel PW Multiplier Vs. Ref. Pulses (>17)

BLM Cell RPM Boundaries

BLM Cell MAF Boundaries

Integrator Delay Vs. Airflow

Integrator Delay Multiplier Vs. Error

Rich/Lean O2 Count Offset Vs. Coolant Temp.

Fast O2 Rich/Lean Threshold Vs. MAF

Rich/Lean O2 Count Offset Vs. Coolant Temp.

O2 Error Reduction Gain Vs. Airflow

Upper Zero Error Reference for Slow O2 R/L Vs. MAF

Lower Zero Error Reference for Slow O2 R/L Vs. MAF

Warm IAC Park (Steps) vs Coolant

Desired Idle Speed vs Coolant Temp.

EGR % Duty Cycle Vs. LV8 Vs. RPM

EGR Duty Cycle Multiplier Vs. Coolant Temp.

Fan Control Coolant Temperatures

Fan PWM % Duty Cycle Vs. ECT

Mass Air Flow 1

Mass Air Flow 2

Mass Air Flow 3

Mass Air Flow 4

Mass Air Flow 5

Mass Air Flow 6

Maximum Mass Air Flow Vs. RPM, (Diag)

Default MAF Value per %TPS Vs. RPM

TCC Lower Load Limit Vs. Speed (High Gear)

TCC Upper Load Limit Vs. Speed (High Gear)

TCC Lower Load Limit Vs. Speed (Low Gears)

TCC Upper Load Limit Vs. Speed (Low Gears)

Shift Light On %TPS Threshold Vs. RPM

Shift Light Off %TPS Threshold Vs. RPM

What values and tables I can change, and then new tune would be burned into a new or erased E-prom 27C128 K

ECM Switch Parameters

VATS Select, X = Enabled

Normally Open Fan Request Input

Sliding Filter for Airflow, X = Enabled

Open Loop Purge

Single Fire Mode

Dual Air Valve

Cansiter Purge when Output Energized

C.A.R.S. Select (X = Enabled)

Manual/Auto Transmission, X = Manual

4th Gear Switch N.O.

TCC Control, (X = RPM else MPH)

Unlock TCC in Decel Fuel C/O

TCC Locked Highway Spark Enable Check

4th Gear Highway Mode Spark Check

TCC/Shift Light Control (0 = TCC)

No Ref. Pulse Diag. (Error 12)

O2 Sensor Diag. (Error 13)

ECT Sensor High Diag. (Error 14)

ECT Sensor Low Diag. (Error 15)

TPS Sensor High Diag. (Error 21)

TPS Sensor Low Diag. (Error 22)

MAT Sensor Low Diagnostic (Error 23)

Vehicle Speed Diag. (Error 24)

MAT Sensor High Diagnostic (Error 25)

EGR Diagnostic (Error 32)

MAF Sensor High (Error 33)

MAF Sensor Low (Error 34)

MAF Burnoff Diag. (Error 36)

Cylinder Select Diagnostic (Error 41)

EST Monitor Diagnostic (Error 42)

Knock Diagnostic (Error 43)

O2 Sensor Lean Diagnostic (Error 44)

O2 Sensor Rich Diagnostic (Error 45)

VATS Diagnostic (Error 46)

EPROM Diagnostic (Error 51)

Missing CalPack Diagnostic (Error 52)

Over-Voltage Diagnostic (Error 53)

Fuel Pump Voltage Diagnostic (Error 54)

ECM Constants

Initial Spark Advance

Cool Compensation Spark Table Bias

Min RPM for Highway Mode Spark

Load Value to Disable Highway Mode Spark

Min Coolant Temp for Highway Mode Spark

Highway Mode Spark Enable Delay

Spark Advance Added in ALDL Mode

Max Spark Advance

Knock Retard Enable RPM Threhold

Knock Retard Delay Time

Stall Saver Spark Disable RPM Threshold

Fuel Cutoff Speed

Fuel Resume Speed

Fuel Cutoff Engine Speed

Fuel Resume Engine Speed

Injector Flow Rate, Single Fire

Injector Flow Rate, Double Fire

Display Injector Flow Rate

Stochiometeric Air Fuel Ratio

Hot O2 Closed Loop Timer

Warm O2 Closed Loop Timer

Cold O2 Closed Loop Timer

Closed Loop Fuel Enable Coolant Temp.

Minimum Delta TPS For Accel. Enrich.

Min Delta TPS A.E. Async Pulse Width

Minimum Delta LV8 For Accel. Enrich.

Max Accel. Enrich. Async Pulse Width

DFCO Enable RPM Threshold

DFCO Disable RPM Threshold

DFCO Enable Load Threshold

DFCO Disable Load Threshold

Max. RPM Decrease/12.5ms To Stay In DFCO

DFCO Enable TPS Threshold

DFCO Disable Vss Threshold

DFCO Enable Coolant Temp.

Decel Enlean Enable Diff. TPS Threshold

Decel Enlean Enable Diff. Load Threshold

Decel Enlean BPW Factor (Low DRP's)

Decel Enlean BPW Factor (High DRP's)

Min Speed for Highway Mode Fuel

Load Value to Disable Highway Mode Fuel

Min Coolant Temp for Highway Mode Fuel

Highway Mode Fuel Enable Delay

Max Time in Highway Fuel Mode

Minimum BLM value

Maximum BLM value

Min. Coolant Temp for BLM Update

Max. Coolant Temp for BLM Update

BLM - Update Rate

BLM Update Cell Amount

BLM Update - Min Pos. Integrator Error

BLM Update - Min Neg. Integrator Error

Minimum Integrator Value

Maximum Integrator Value

Startup Enrichment Decay Rate

Min Coolant Temp. For High Temp P.E. AFR

Idle Speed Adder in Park/Neutral

Idle Speed Adder A/C On

IAC Startup Park Position

IAC Startup Delay Time

Warm Park IAC Steps Adder - A/C On

IAC Control Deadband RPM Error (in P/N)

IAC Control Deadband RPM Error (Drive)

IAC Learn - Min Coolant Temp

IAC Learn - Max Coolant Temp

Throt. Follower IAC Steps Added in Drive

EGR On, (TPS)

EGR Off, (TPS)

Min. MAT to Enable EGR

MAF High Diagnostic (Error 33) Threshold

TCC Unlock Speed (Low Gears)

TCC Lock Speed (Low Gears)

TCC Unlock Speed (High Gear)

TCC Lock Speed (High Gear)

TCC Unlock Prevention Speed

TCC Enable Coolant Temp. Threshold

Min. Load Limit for TCC Lock, Low Speed

Min. Load Limit for TCC Lock, High Speed

TCC Min Load Limit Hysteresis

TCC Min Load Limit High/Low Speed Thresh

Shift Light Enable Coolant Temp. Thresh.

Shift Light Enable Vehicle Speed Thresh.

Shift Light Enable %TPS Threshold

Shift Light Enable RPM Threshold

Shift Light Disable RPM Threshold

Shift Light Force On RPM Threshold

Shift Light Force On Disable RPM Thresh

Min Canister Purge Duty Cycle (Low TPS)

Canister Purge - Coolant Temp. Enable

Canister Purge - Vehicle Speed Enable

Canister Purge - TPS Enable

Canister Purge - Vehicle Speed Disable

Canister Purge - TPS Disable

AIR Divert Enable Coolant Temp.

AIR Divert O2 mV Rich/Lean Thresh Reduc.

Default MAF Maximum %TPS Value

Default MAF IAC Scale Factor

Minimum Default MAF Value

Number of Cylinders

Tables

ECM Switch Table

ECM Constant Table

Main Spark Advance Vs. RPM Vs. Load

Cool Compensation Spark Vs. Load Vs. Cool. Temp.

Spark Advance In Power Enrich. Vs. RPM

Knock Attack Rate Vs. RPM (Deg/msec)

Knock Recovery Rate Vs. RPM (%/sec)

Maximum Knock Retard Vs RPM In P.E.

Maximum Knock Retard Vs Load, (Not In P. E.)

Highway Mode Spark Advance Vs. Load

Start Up Spark Advance Vs. Coolant Temp.

Startup Spark Advance Decay Step Vs. Cool. Temp.

Startup Spark Advance Decay Delay Vs. Cool. Temp.

Stall Saver Spark Enable RPM Thresholds

%TPS To Enable Power Enrich. Vs RPM (Normal)

%TPS To Enable Power Enrich Vs RPM (Hot)

P. E. %ChangeTo Fuel/Air Ratio Vs Coolant Temp.

P. E. %Change To Fuel/Air Ratio Vs RPM

Open Loop Fuel/Air Ratio %Change Vs.Load

Open Loop Fuel/Air Ratio %Change Vs. Coolant Temp.

Startup Fuel/Air Ratio %Change Vs. Coolant Temp.

Startup Enrich Decay Amount Vs. Startup Cool Temp.

Startup Enrich Decay Delay Vs. Startup Cool Temp.

Highway Mode AFR Vs. Load

Injector Pulse Width Correction vs Battery Voltage

Low Pulse Width Injector Offset Vs. BPW

Accel. Enrich %BPW Factor Vs Async Pulse

No. of Accel Enrich Async Pulses Vs. Coolant Temp.

Accel. Enrich. Async Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Factor Vs. Delta LV8

LV8 Accel Enrich Coolant Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Decay Rate Vs. Coolant Temp.

Crank Fuel Pulse Width Vs. Coolant Temp.

Crank Fuel Pulse Width Multiplier Vs. TPS

Crank Fuel PW Multiplier Vs. Ref. Pulses (1-16)

Crank Fuel PW Multiplier Vs. Ref. Pulses (>17)

BLM Cell RPM Boundaries

BLM Cell MAF Boundaries

Integrator Delay Vs. Airflow

Integrator Delay Multiplier Vs. Error

Rich/Lean O2 Count Offset Vs. Coolant Temp.

Fast O2 Rich/Lean Threshold Vs. MAF

Rich/Lean O2 Count Offset Vs. Coolant Temp.

O2 Error Reduction Gain Vs. Airflow

Upper Zero Error Reference for Slow O2 R/L Vs. MAF

Lower Zero Error Reference for Slow O2 R/L Vs. MAF

Warm IAC Park (Steps) vs Coolant

Desired Idle Speed vs Coolant Temp.

EGR % Duty Cycle Vs. LV8 Vs. RPM

EGR Duty Cycle Multiplier Vs. Coolant Temp.

Fan Control Coolant Temperatures

Fan PWM % Duty Cycle Vs. ECT

Mass Air Flow 1

Mass Air Flow 2

Mass Air Flow 3

Mass Air Flow 4

Mass Air Flow 5

Mass Air Flow 6

Maximum Mass Air Flow Vs. RPM, (Diag)

Default MAF Value per %TPS Vs. RPM

TCC Lower Load Limit Vs. Speed (High Gear)

TCC Upper Load Limit Vs. Speed (High Gear)

TCC Lower Load Limit Vs. Speed (Low Gears)

TCC Upper Load Limit Vs. Speed (Low Gears)

Shift Light On %TPS Threshold Vs. RPM

Shift Light Off %TPS Threshold Vs. RPM

Steven Smith

CCCUK Member

Very interesting, just checked and we can get the same one from Amazon in the UK for £100.You can do a search as example on Amazon as several to choose from

Example this one is $60 and can burn/flash into many types of E-proms

GM used through the years for vehicles ECMs,

E-prom sizes of 32, 128, 256 and 512 K bytes so want a burner that can handle different sizes and E-proms that have 24 or 28 pins

There are E-prom tools come with the burner, cable and software that runs on MS-Windows

In the case such as an 1989 C4 the ECM uses a 27C128 E-prom which has 28 pins

This means that E-prom hold 128K bytes of data

Also, may want to get an E-prom eraser to be able to delete data on a used E-proms to allow it to be

burned again with new data

Here is from Amazon, programmers, erasers and E-Proms

View attachment 28825View attachment 28826

That's definitely something I will look into getting for my 86.

teamzr1

Supporting vendor

For 1986 C4 only what I can touch and change in the GM calibration

But uses the same sized E-prom of 27C128 that the 1989 uses

ECM Switch Parameters

VATS Select

Base PW Calibration Method (X = Calc.)

Normally Open Fan Request Input

Manual/Auto Transmission, X = Manual

Overdrive Default Off/On (X = On)

Use TCC Output for Shift Light

No Ref. Pulse Diagnostic (Err 12)

O2 Sensor Diagnostic (Err 13)

CTS Sensor High Diagnostic (Err 14)

CTS Sensor Low Diagnostic (Err 15)

TPS Sensor High Diagnostic (Err 21)

TPS Sensor Low Diagnostic (Err 22)

MAT Sensor Low Diagnostic (Err 23)

Vehicle Speed Diagnostics (Err 24)

MAT Sensor High Diagnostic (Err 25)

EGR Diagnostics (Err 32)

MAF High Diagnostics (Err 33)

MAF Low Diagnostic (Err 34)

Burn Off Diagnostic (Err 36)

Cyl. Select Diagnostic (Err 41)

EST Monitor Diagnostic (Err 42)

Knock Diagnostics (Err 43)

O2 Sensor Lean Diagnostic (Err 44)

O2 Sensor Rich Diagnostic (Err 45)

VATS Diagnostics (Err 46)

Missing Cal Pack (Err 52)

Over Voltage Diagnostic (Err 53)

Fuel Pump Voltage (Err 54)

ECM Constants

Initial Spark Advance

Max Spark Advance

Cool. Comp. Spark Spark Bias

Highway Mode Spark Enable Coolant Temp.

Highway Mode Spark Max Load Threshold

Highway Mode Spark Enable RPM Treshold

Highway Mode Spark Enable Delay Time

Knock Retard Enable RPM Threhold

Knock Retard Enable MPH Threhold

Knock Retard Enable Cool. Temp. Thresh.

Max Knock Retard (Not in P.E.)

Default Knock Retard if MALF 43

Fuel Cut Off Vehicle Speed

Fuel Resume Vehicle Speed

Fuel Cut Off RPM

Fuel Resume RPM

Fan On Coolant Temp Threshold (A/C On)

Fan Off Coolant Temp Threshold (A/C On)

Fan On Coolant Temp Threshold (A/C Off)

Fan Off Coolant Temp Threshold (A/C Off)

Injector Flow Rate - Single Fire

Injector Flow Rate - Double Fire

Max Accel. Enrich. Async Pulse Width

Minimum Delta TPS For Accel. Enrich.

Minimum Delta LV8 For Accel. Enrich.

Closed Loop Fuel Enable Cool. Temp.

Hot O2 Timer

Warm O2 Timer

Cold O2 Timer

Maximum BLM Value

Minimum BLM Value

Min. Coolant Temp for BLM Update

Max. Coolant Temp for BLM Update

Fast O2 R/L Hysteresis

Fast O2 R/L Hysteresis - Air Diverted

Decel Enlean Enable Delta TPS Thresh.

Decel Enlean Enable Delta LV8 Thresh.

Decel Enlean BPW Multiplier

MAF High Diagnostic (Error 33) Threshold

EGR Off (%TPS)

EGR On (%TPS)

Min. MAT to Enable EGR

TCC Unlock Speed (Low Gears)

TCC Lock Speed (Low Gears)

TCC Unlock Speed (High Gears)

TCC Lock Speed (High Gears)

TCC Unlock Prevent/Auto O/D Engage Speed

TCC Enable Coolant Temp. Threshold

Min. Load Limit for TCC Lock, Low Speed

Min. Load Limit for TCC Lock, High Speed

TCC Min Load Limit Hysteresis

TCC Min Load Limit High/Low Speed Thresh

Shifter Kickdown Prevent RPM Threshold

TPS Kickdown/TCC Unlock Prevent -1st Gr.

TPS Kickdown/TCC Unlock Prevent-Not 1st

Idle Speed Adder in Park/Neutral

Idle Speed Adder for A/C On

IAC Startup Park Position

IAC Startup Delay Time

IAC Control Deadband RPM Error (in P/N)

IAC Control Deadband RPM Error (Drive)

IAC Steps added to Warm Park, A/C On

IAC Steps added for Cold Engine

IAC Gain Scalar for Prop & Deriv (P/N)

IAC RPM Rate Deadband, Idle Stability

DFCO Enable RPM Threshold

DFCO Disable RPM Threshold

DFCO Enable LV8 Threshold

DFCO Disable LV8 Threshold

DFCO Disable TPS Threshold

DFCO Disable MPH Threshold

DFCO Enable Cool Temp Threshold

DFCO Throttle Follower Default %TPS

DFCO Stall Saver T/F %TPS Correction

DFCO Stall Saver T/F %TPS Corr. Duration

DFCO Stall Saver Async Inj. Pulse Width

DFCO Stall Saver Async Inj. Pulses

Stall Saver Spark Correction Enable RPM

Stall Saver Spark Correction Disable RPM

Throttle Follower Step Period - in P/N

Throttle Follower Step Period - in Drive

T/F Step Period Correction Vs. Speed

T/F Step Period Correction in O/L Idle

Throttle Follower Slope Gain

Max. Throttle Follower Steps - in Drive

P/N Throttle Follower Multiplier

Closed Loop Idle Enable Vehicle Speed

Throttle Follower Adder - Vehicle Moving

AIR Control Enable Coolant Temp.

Shift Light Enable Coolant Temp. Thresh.

Shift Light Enable Vehicle Speed Thresh.

Shift Light Enable %TPS Threshold

Shift Light Enable LV8 Threshold

Shift Light Enable RPM Threshold

Shift Light Disable RPM Threshold

Shift Light Force On RPM Threshold

Shift Light Force On Disable RPM Thresh

Number of Cylinders

Display Injector Flow Rate

Tables

ECM Switch Table

ECM Constant Table

Main Spark Advance Vs. RPM Vs. Load

Cool. Comp. Spark Adv. Vs. RPM Vs. Cool. Temp.

Highway Mode Spark Advance Vs. Load

Startup Spark Advance Vs. Startup Cool. Temp.

Startup Spark Advance Decay Delay Vs Startup Cool.

Startup Spark Adv. Decay Period Vs. Startup Cool.

Startup Spark Adv. Decay Step Vs. Startup Cool.

Knock Retard Attack Rate Vs. RPM

Knock Retard Recovery Rate Vs. RPM

Max Knock Retard in WOT

WOT %Change To Fuel/Air Ratio Vs. Coolant Temp.

WOT %Change To Fuel/Air Ratio Vs. RPM

%TPS To Enable WOT Vs RPM

Open Loop Fuel/Air Ratio %Change Vs. Coolant Temp.

Open Loop Fuel/Air Ratio %Change Vs. Load

Startup Fuel/Air Ratio %Change Vs. Coolant Temp.

Warm IAC Park (Steps) Vs. Coolant Temp.

Desired Idle Speed vs Coolant Temp.

Mass Air Flow Table #1

Mass Air Flow Table #2

Mass Air Flow Table #3

Mass Air Flow Table #4

Mass Air Flow Table #5

Mass Air Flow Table #6

Max. Air Flow Vs. RPM

BPW Fuel Table Vs Load Vs RPM

Injector PW Correction Vs. Battery Voltage

Accel. Enrich %BPW Factor Vs Async Pulse

No. of Accel Enrich Async Pulses Vs. Coolant Temp.

Accel. Enrich. Async Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Factor Vs. Delta LV8

LV8 Accel Enrich Coolant Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Decay Rate Vs. Coolant Temp.

Crank Fuel Pulse Width Vs. Coolant Temp.

Crank Fuel Multiplier Vs. Reference Pulses

Crank Fuel Pulse Width Multiplier Vs. TPS

BLM Cell RPM Boundaries

BLM Cell MAF Boundaries

Fast O2 Rich/Lean Threshold Vs. MAF

Rich/Lean O2 Count Offset Vs. Coolant Temp.

Upper Zero Error Reference for Slow O2 R/L Vs. MAF

Lower Zero Error Reference for Slow O2 R/L Vs. MAF

Fan PWM Duty Cycle Vs. Coolant Temp.

EGR % Duty Cycle Vs. LV8 Vs. RPM

TCC Unlock %TPS (Not In 4th) Vs. MPH

TCC Lock %TPS (Not In 4th) Vs MPH

TCC Unlock %TPS (In 4th) Vs MPH

TCC Lock %TPS (In 4th) Vs MPH

Shift Light On %TPS Threshold Vs. RPM

Shift Light Off %TPS Threshold Vs. RPM

Shift Light On Delay Time Vs. %TPS

But uses the same sized E-prom of 27C128 that the 1989 uses

ECM Switch Parameters

VATS Select

Base PW Calibration Method (X = Calc.)

Normally Open Fan Request Input

Manual/Auto Transmission, X = Manual

Overdrive Default Off/On (X = On)

Use TCC Output for Shift Light

No Ref. Pulse Diagnostic (Err 12)

O2 Sensor Diagnostic (Err 13)

CTS Sensor High Diagnostic (Err 14)

CTS Sensor Low Diagnostic (Err 15)

TPS Sensor High Diagnostic (Err 21)

TPS Sensor Low Diagnostic (Err 22)

MAT Sensor Low Diagnostic (Err 23)

Vehicle Speed Diagnostics (Err 24)

MAT Sensor High Diagnostic (Err 25)

EGR Diagnostics (Err 32)

MAF High Diagnostics (Err 33)

MAF Low Diagnostic (Err 34)

Burn Off Diagnostic (Err 36)

Cyl. Select Diagnostic (Err 41)

EST Monitor Diagnostic (Err 42)

Knock Diagnostics (Err 43)

O2 Sensor Lean Diagnostic (Err 44)

O2 Sensor Rich Diagnostic (Err 45)

VATS Diagnostics (Err 46)

Missing Cal Pack (Err 52)

Over Voltage Diagnostic (Err 53)

Fuel Pump Voltage (Err 54)

ECM Constants

Initial Spark Advance

Max Spark Advance

Cool. Comp. Spark Spark Bias

Highway Mode Spark Enable Coolant Temp.

Highway Mode Spark Max Load Threshold

Highway Mode Spark Enable RPM Treshold

Highway Mode Spark Enable Delay Time

Knock Retard Enable RPM Threhold

Knock Retard Enable MPH Threhold

Knock Retard Enable Cool. Temp. Thresh.

Max Knock Retard (Not in P.E.)

Default Knock Retard if MALF 43

Fuel Cut Off Vehicle Speed

Fuel Resume Vehicle Speed

Fuel Cut Off RPM

Fuel Resume RPM

Fan On Coolant Temp Threshold (A/C On)

Fan Off Coolant Temp Threshold (A/C On)

Fan On Coolant Temp Threshold (A/C Off)

Fan Off Coolant Temp Threshold (A/C Off)

Injector Flow Rate - Single Fire

Injector Flow Rate - Double Fire

Max Accel. Enrich. Async Pulse Width

Minimum Delta TPS For Accel. Enrich.

Minimum Delta LV8 For Accel. Enrich.

Closed Loop Fuel Enable Cool. Temp.

Hot O2 Timer

Warm O2 Timer

Cold O2 Timer

Maximum BLM Value

Minimum BLM Value

Min. Coolant Temp for BLM Update

Max. Coolant Temp for BLM Update

Fast O2 R/L Hysteresis

Fast O2 R/L Hysteresis - Air Diverted

Decel Enlean Enable Delta TPS Thresh.

Decel Enlean Enable Delta LV8 Thresh.

Decel Enlean BPW Multiplier

MAF High Diagnostic (Error 33) Threshold

EGR Off (%TPS)

EGR On (%TPS)

Min. MAT to Enable EGR

TCC Unlock Speed (Low Gears)

TCC Lock Speed (Low Gears)

TCC Unlock Speed (High Gears)

TCC Lock Speed (High Gears)

TCC Unlock Prevent/Auto O/D Engage Speed

TCC Enable Coolant Temp. Threshold

Min. Load Limit for TCC Lock, Low Speed

Min. Load Limit for TCC Lock, High Speed

TCC Min Load Limit Hysteresis

TCC Min Load Limit High/Low Speed Thresh

Shifter Kickdown Prevent RPM Threshold

TPS Kickdown/TCC Unlock Prevent -1st Gr.

TPS Kickdown/TCC Unlock Prevent-Not 1st

Idle Speed Adder in Park/Neutral

Idle Speed Adder for A/C On

IAC Startup Park Position

IAC Startup Delay Time

IAC Control Deadband RPM Error (in P/N)

IAC Control Deadband RPM Error (Drive)

IAC Steps added to Warm Park, A/C On

IAC Steps added for Cold Engine

IAC Gain Scalar for Prop & Deriv (P/N)

IAC RPM Rate Deadband, Idle Stability

DFCO Enable RPM Threshold

DFCO Disable RPM Threshold

DFCO Enable LV8 Threshold

DFCO Disable LV8 Threshold

DFCO Disable TPS Threshold

DFCO Disable MPH Threshold

DFCO Enable Cool Temp Threshold

DFCO Throttle Follower Default %TPS

DFCO Stall Saver T/F %TPS Correction

DFCO Stall Saver T/F %TPS Corr. Duration

DFCO Stall Saver Async Inj. Pulse Width

DFCO Stall Saver Async Inj. Pulses

Stall Saver Spark Correction Enable RPM

Stall Saver Spark Correction Disable RPM

Throttle Follower Step Period - in P/N

Throttle Follower Step Period - in Drive

T/F Step Period Correction Vs. Speed

T/F Step Period Correction in O/L Idle

Throttle Follower Slope Gain

Max. Throttle Follower Steps - in Drive

P/N Throttle Follower Multiplier

Closed Loop Idle Enable Vehicle Speed

Throttle Follower Adder - Vehicle Moving

AIR Control Enable Coolant Temp.

Shift Light Enable Coolant Temp. Thresh.

Shift Light Enable Vehicle Speed Thresh.

Shift Light Enable %TPS Threshold

Shift Light Enable LV8 Threshold

Shift Light Enable RPM Threshold

Shift Light Disable RPM Threshold

Shift Light Force On RPM Threshold

Shift Light Force On Disable RPM Thresh

Number of Cylinders

Display Injector Flow Rate

Tables

ECM Switch Table

ECM Constant Table

Main Spark Advance Vs. RPM Vs. Load

Cool. Comp. Spark Adv. Vs. RPM Vs. Cool. Temp.

Highway Mode Spark Advance Vs. Load

Startup Spark Advance Vs. Startup Cool. Temp.

Startup Spark Advance Decay Delay Vs Startup Cool.

Startup Spark Adv. Decay Period Vs. Startup Cool.

Startup Spark Adv. Decay Step Vs. Startup Cool.

Knock Retard Attack Rate Vs. RPM

Knock Retard Recovery Rate Vs. RPM

Max Knock Retard in WOT

WOT %Change To Fuel/Air Ratio Vs. Coolant Temp.

WOT %Change To Fuel/Air Ratio Vs. RPM

%TPS To Enable WOT Vs RPM

Open Loop Fuel/Air Ratio %Change Vs. Coolant Temp.

Open Loop Fuel/Air Ratio %Change Vs. Load

Startup Fuel/Air Ratio %Change Vs. Coolant Temp.

Warm IAC Park (Steps) Vs. Coolant Temp.

Desired Idle Speed vs Coolant Temp.

Mass Air Flow Table #1

Mass Air Flow Table #2

Mass Air Flow Table #3

Mass Air Flow Table #4

Mass Air Flow Table #5

Mass Air Flow Table #6

Max. Air Flow Vs. RPM

BPW Fuel Table Vs Load Vs RPM

Injector PW Correction Vs. Battery Voltage

Accel. Enrich %BPW Factor Vs Async Pulse

No. of Accel Enrich Async Pulses Vs. Coolant Temp.

Accel. Enrich. Async Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Factor Vs. Delta LV8

LV8 Accel Enrich Coolant Factor Vs. Coolant Temp.

LV8 Accel. Enrich. Decay Rate Vs. Coolant Temp.

Crank Fuel Pulse Width Vs. Coolant Temp.

Crank Fuel Multiplier Vs. Reference Pulses

Crank Fuel Pulse Width Multiplier Vs. TPS

BLM Cell RPM Boundaries

BLM Cell MAF Boundaries

Fast O2 Rich/Lean Threshold Vs. MAF

Rich/Lean O2 Count Offset Vs. Coolant Temp.

Upper Zero Error Reference for Slow O2 R/L Vs. MAF

Lower Zero Error Reference for Slow O2 R/L Vs. MAF

Fan PWM Duty Cycle Vs. Coolant Temp.

EGR % Duty Cycle Vs. LV8 Vs. RPM

TCC Unlock %TPS (Not In 4th) Vs. MPH

TCC Lock %TPS (Not In 4th) Vs MPH

TCC Unlock %TPS (In 4th) Vs MPH

TCC Lock %TPS (In 4th) Vs MPH

Shift Light On %TPS Threshold Vs. RPM

Shift Light Off %TPS Threshold Vs. RPM

Shift Light On Delay Time Vs. %TPS

Steven Smith

CCCUK Member

Double check as this is my 86, yours could be differentokay so this is the coolant level sensor:- understood- will get hold of a new one.

View attachment 28828