You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil flow

- Thread starter johng

- Start date

johng

CCCUK Member

Hey guys I need some more advice from the engine gurus.

Haven't been able to work out what the tapping sound is, so decided to just keep using the boat anyway. The idea being that either it wasn't important and nothing bad would happen, or else something would happen and that might allow us to determine what the problem was!!!

Well something has now happened. We have water in the oil and water in the front right hand side cylinder.

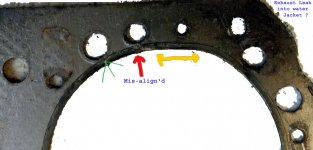

We took the right hand head off today and I think we have a problem with the head gasket, if you look at this photo there is some damage by the red arrow between the cylinder and a water passage. Also the gasket doesn't look circular in the area of the yellow arrow

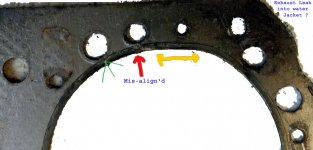

Here's a close up of the damage

Does this look like the problem to you? I've never actually seen a failed head gasket myself.

Any ideas what could have caused this? The boat engine has been run for several days with no sign of water in the oil or any misfiring (which certainly did happen on our last trip out). The head bolts were still all tight. Also why might the gasket not be circular? Does this indicate anything?

Could a leaking head gasket have caused the tapping sound?

Haven't been able to work out what the tapping sound is, so decided to just keep using the boat anyway. The idea being that either it wasn't important and nothing bad would happen, or else something would happen and that might allow us to determine what the problem was!!!

Well something has now happened. We have water in the oil and water in the front right hand side cylinder.

We took the right hand head off today and I think we have a problem with the head gasket, if you look at this photo there is some damage by the red arrow between the cylinder and a water passage. Also the gasket doesn't look circular in the area of the yellow arrow

Here's a close up of the damage

Does this look like the problem to you? I've never actually seen a failed head gasket myself.

Any ideas what could have caused this? The boat engine has been run for several days with no sign of water in the oil or any misfiring (which certainly did happen on our last trip out). The head bolts were still all tight. Also why might the gasket not be circular? Does this indicate anything?

Could a leaking head gasket have caused the tapping sound?

Oneball

CCCUK Member

The hole in head gaskets isn’t always round so that bit being straight isn’t an immediate issue, you’d need to compare it with a new one.

What is an issue is that you can see where the water or oil ways are overlapping the fire ring. Who built the engine? I’d say it’s the wrong head gasket.

What is an issue is that you can see where the water or oil ways are overlapping the fire ring. Who built the engine? I’d say it’s the wrong head gasket.

Oneball

CCCUK Member

Yep gasket is usually a bit larger than the cylinder. Green arrow is where something isn’t right (probably the same on the bit that’s gone you just can’t see it) You don’t want anything overlapping the fire ring, you’ll just end up with the gasket failing.

Are they the right heads? Do you know whether it was head or block that was that side of the gasket.

Are they the right heads? Do you know whether it was head or block that was that side of the gasket.

johng

CCCUK Member

The damage is head side of the gasket. The hole with the green arrow is a head bolt.

I'm pretty sure they are the right heads (but not certain!). The heads came from a Blazer built in the same year as the boat and from what I could find out there were no changes made for several years prior to this.

I'm pretty sure they are the right heads (but not certain!). The heads came from a Blazer built in the same year as the boat and from what I could find out there were no changes made for several years prior to this.

Chuffer

CCCUK Member

As an aside to your water contamination and gasket problems , how does the engine cooling system function ? Many marine engines draw cooling water in from below the water line , through the engine and out through a discharge pipe in a constant cycle . In a salt water environment this will cause corrosion issues . Just a thought .The damage is head side of the gasket. The hole with the green arrow is a head bolt.

I'm pretty sure they are the right heads (but not certain!). The heads came from a Blazer built in the same year as the boat and from what I could find out there were no changes made for several years prior to this.

Forrest Gump

CCCUK regional rep

teamzr1

Supporting vendor

Just thinking out loud

1. Are the head bolts required to be torque to yield, and if so where new one used as required ?

2. Was the proper passes used to meet the bolt torque correctly (after a few cold hot idle cycles, rechecked torque to spec) ?

3. Is it possible head gaskets were used for the wrong head side (holes for water jackets line up) ?

4. looks like that right corner of image was leaking exhaust into water jacket

5. lifters, maybe clogged up now and would not proper flow through push rods

6. good chance of hydro locking engine if kept running like this

7. If using anti-freeze and coolant was mixing with oil then lifters could be gummed up

8. Check each lifter that they are still pumped up, should not be able to push down with a finger,

1. Are the head bolts required to be torque to yield, and if so where new one used as required ?

2. Was the proper passes used to meet the bolt torque correctly (after a few cold hot idle cycles, rechecked torque to spec) ?

3. Is it possible head gaskets were used for the wrong head side (holes for water jackets line up) ?

4. looks like that right corner of image was leaking exhaust into water jacket

5. lifters, maybe clogged up now and would not proper flow through push rods

6. good chance of hydro locking engine if kept running like this

7. If using anti-freeze and coolant was mixing with oil then lifters could be gummed up

8. Check each lifter that they are still pumped up, should not be able to push down with a finger,

Last edited:

johng

CCCUK Member

Thanks guys,

Chuffer the cooling system does flow salt water through the engine, hence the original heads corroded through (after 15 years)

Ross no idea and not sure where I'd get them either. I've ordered replacement gaskets from Rockauto should be here next week.

Andy my head bolts are the same pattern as yours, your one at the bottom of the photo is the equivalent one to mine that sits on the sealing ring and doesn't have much clearance either.

Team_ZR1

1. No

2. Yes

3 . Its possible

4. Don't think so, I think that is just the light

5. I'm half way through opening up and cleaning out all the lifters, they are full of emulsion

6. Yes, luckily it didn't

7. No antifreeze just sea water!

8. Lifters are now not pumped as I've taken them apart

Chuffer the cooling system does flow salt water through the engine, hence the original heads corroded through (after 15 years)

Ross no idea and not sure where I'd get them either. I've ordered replacement gaskets from Rockauto should be here next week.

Andy my head bolts are the same pattern as yours, your one at the bottom of the photo is the equivalent one to mine that sits on the sealing ring and doesn't have much clearance either.

Team_ZR1

1. No

2. Yes

3 . Its possible

4. Don't think so, I think that is just the light

5. I'm half way through opening up and cleaning out all the lifters, they are full of emulsion

6. Yes, luckily it didn't

7. No antifreeze just sea water!

8. Lifters are now not pumped as I've taken them apart

HJG

CCCUK Member

Possibly if leaking combustion gases on one cylinder (one event per 720deg revolution of the crank, lining up with your 5Hz at idle).Could a leaking head gasket have caused the tapping sound?

Chuffer

CCCUK Member

Johng , If your boat engine has a `direct ` sea water cooling system rather than an `indirect ` system whereby the coolant is a sealed system and cooled via a heat exchanger there will be be a continuous effect of salt water corrosion in the all the cooling passages of the block / cylinder head . My understanding is that such engines should be stripped regularly and acid washed to remove the corrosion . If your engine had run for 15 years before you had the heads off no wonder it was "eaten away" . Marine engines with a heater exchanger system should have the exchangers removed annualy to be acid washed and maintained .

johng

CCCUK Member

Chuffer, stripping the engine every year sounds like too much effort and expense for me. I think I'd rather just replace the exhaust every 10 years (mine lasted 13 years before rotting through) and heads every 12 years. Presumably even if you acid etch it every year, corrosion is still going to take place. Anyway I probably don't have to keep the boat running for too many more years, I'm not sure I will still be waterskiing at 70.

Chuffer

CCCUK Member

I have no personal experience of marine inboard boat engines , only water cooled outboards and an air cooled twin cylinder traditional narrowboat but am just speculating that the hostile salt water environment may have a lot to do with the cause of your problems . It is certainly a different kettle of fish to a Chevy V8 in a Corvette . Unless the Corvette happens to be a small warship !

Hope get it sorted and keep up the water skiing into your dotage .

Hope get it sorted and keep up the water skiing into your dotage .

johng

CCCUK Member

Having just finished stripping down and cleaning up all the lifters, I've got another rather detailed question for the gurus among us. Under the end cap of the lifter there is a plate that controls the flow of oil up to the rockers. On my lifters this plate has a shape pressed into it. The question is which way up does this pressing go? These are all brand new lifters, I installed a couple of months ago. Of the 16 lifters I have, 13 have the centre raised part on the end cap side as per this first photo.

The remaining 3 were the other way up. Does anyone know if this makes any difference?

The remaining 3 were the other way up. Does anyone know if this makes any difference?