You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reverse lock out query

- Thread starter Mad4slalom

- Start date

antijam

CCCUK Member

The tube carrying the lever runs in a plastic sleeve inside the steering column and is not designed for lubrication. If yours is stiff (and it's not just the cable binding) you could try some spray lubricant to see if it eases it off. Many of these have been disconnected when stiffness can be a virtue since the lever then remains up without needing to be tied.

Mad4slalom

Well-known user

Thank you both, it just looked dry and I wondered . Not stiff but I tried it once after reconnecting the cable and it felt a bit stiffer than before we disturbed it. I will check cable clamp position on side of gbox to check outer cable is clamped in the same position. Will lube cable and arm a bit too. It all still looks very new from the rebuild tho that was over ten years ago.They have ,due to the age and lack of lube to bend at the transmission, so a slow bend in the cable to the transmission and good lubrication of the cable and on the lock arm will help

Mad4slalom

Well-known user

It doesn’t look like your rag joint is properly connected to the steering column shaft.

Mad4slalom

Well-known user

Are you looking at the splined section at the bottom of my pic?eek! Tell me more, funny that, as tim P (I think it was) asked me if I needed a rag joint a few weeks ago! What do you think my issue is ? TiA

Oneball

CCCUK Member

Yes. See the flat section milled into it. The clamp bolt that goes through the rag joint should sit in that area so even if it is loose the joint can’t slip off the shaft. Could be your steering column has been collapsed slightly or just the rag joint is too far onto the box.Are you looking at the splined section at the bottom of my pic?

Mad4slalom

Well-known user

Ah yes , I had a similar safety thing on my beach buggy joint, I will investigate in a bit and take a picture of the actual joint.Yes. See the flat section milled into it. The clamp bolt that goes through the rag joint should sit in that area so even if it is loose the joint can’t slip off the shaft. Could be your steering column has been collapsed slightly or just the rag joint is too far onto the box.

Mad4slalom

Well-known user

Morning gavin, do you. Remember we spoke about the flat tool to lock the shifter levers when setting the shift rod adjustment? Were you talking about the stock shifter? Mine has a hurst comp, and they describe round holes that you insert a drill bit or screwdriver to align the shifter levers into neutral before adjusting the rods.They have ,due to the age and lack of lube to bend at the transmission, so a slow bend in the cable to the transmission and good lubrication of the cable and on the lock arm will help

Just a thought , as a quick way to check adjustment , can I put gearstick into neutral , with the rods still connected and then insert a drill bit into the holes in the shift levers , and if they are in alignment then adjustment is ok ? Or do I still need to make up the flat tool ?

Hope this makes sense !

Mad4slalom

Well-known user

Thanks both, I will take another pic in a minute and compareThe rag joint connection should look like this.....

View attachment 27111

As Oneball suggests, I suspect your column has been partly collapsed. This could easily have resulted from some p.o. struggling with column removal in the past.

Oneball

CCCUK Member

Hurst is super easy. Yes exactly what you say. Think the hole is 1/4”. The flat plate is just for the stock shifter,Morning gavin, do you. Remember we spoke about the flat tool to lock the shifter levers when setting the shift rod adjustment? Were you talking about the stock shifter? Mine has a hurst comp, and they describe round holes that you insert a drill bit or screwdriver to align the shifter levers into neutral before adjusting the rods.

Just a thought , as a quick way to check adjustment , can I put gearstick into neutral , with the rods still connected and then insert a drill bit into the holes in the shift levers , and if they are in alignment then adjustment is ok ? Or do I still need to make up the flat tool ?

Hope this makes sense !

To adjust if you need:

Disconnect the rods. Longish bolt through the holes in the shifter from underneath. Reconnect the rods so they slip into the holes easily. Think you need to do it reverse, 3/4, 1/2. But that bit is pretty obvious when you’re under there.

Mad4slalom

Well-known user

Many thanks , back on the ramp later then. I have lubed the lock out lever but I will check the lock out cable to gearbox clamp as I think it may have moved along abit and created a tighter bend as it is a bit stiffer than before .Hurst is super easy. Yes exactly what you say. Think the hole is 1/4”. The flat plate is just for the stock shifter,

To adjust if you need:

Disconnect the rods. Longish bolt through the holes in the shifter from underneath. Reconnect the rods so they slip into the holes easily. Think you need to do it reverse, 3/4, 1/2. But that bit is pretty obvious when you’re under there.

Mad4slalom

Well-known user

Here is a better pic , looks wrong for sure, any suggestions as to what I should do, I thought that the bolt ( on the buggy) could Only fit through in the correct spot, this may be different. I would like to make sure I am not going to turn left instead of right!!The rag joint connection should look like this.....

View attachment 27111

As Oneball suggests, I suspect your column has been partly collapsed. This could easily have resulted from some p.o. struggling with column removal in the past.

Mad4slalom

Well-known user

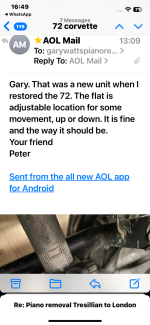

I have sent the pic to peter in the usa who restored it . I suspect there is another detent where the bolt is now , otherwise the bolt wouldnt fit through ? He will be able to explain Hopefully.Here is a better pic , looks wrong for sure, any suggestions as to what I should do, I thought that the bolt ( on the buggy) could Only fit through in the correct spot, this may be different. I would like to make sure I am not going to turn left instead of right!!View attachment 27112

Oneball

CCCUK Member

Mad4slalom

Well-known user

That sounds a good plan thank youI thought it’d be much nearer the end of the column than that. I thought the flat bit was shorter, but it looks like the bolt is on the flat bit. If the bottom of the rag joint is right on the box case I’d probably just move it up the column and steering box a bit to centralise it slightly.

View attachment 27113

Mad4slalom

Well-known user

Po’s reply from the statesI thought it’d be much nearer the end of the column than that. I thought the flat bit was shorter, but it looks like the bolt is on the flat bit. If the bottom of the rag joint is right on the box case I’d probably just move it up the column and steering box a bit to centralise it slightly.

View attachment 27113

Emc

Supporting vendor

If your shifter is a hurst, that uses an Allen key to hold the shifter in neutralMorning gavin, do you. Remember we spoke about the flat tool to lock the shifter levers when setting the shift rod adjustment? Were you talking about the stock shifter? Mine has a hurst comp, and they describe round holes that you insert a drill bit or screwdriver to align the shifter levers into neutral before adjusting the rods.

Just a thought , as a quick way to check adjustment , can I put gearstick into neutral , with the rods still connected and then insert a drill bit into the holes in the shift levers , and if they are in alignment then adjustment is ok ? Or do I still need to make up the flat tool ?

Hope this makes sense !