When I bought my '71 three years ago the steering, in common with many C3's, was best described as 'wayward'. The rag joint was obviously shot and the power steering system was an oily mess. I checked the ball joints in the linkage for wear but all seemed tight. I replaced the rag joint and the power steering valve, ram and hoses, fiddled with the adjuster on top of the steering box and found steering considerably improved though still far from precise.

Having recently rebuilt most of the rear suspension with new spring, shocks, drive shafts, struts and trailing arms I needed to get my initial realignment checked professionally. Easier said than done in this neck of Little Britain; all the local tyre shops have gone computerised and when presented with a 50 year old Yank - computer says 'No'.

Eventually discover a local garagiste out in the sticks who has both the equipment and the nous to do a full 4-wheel alignment on a C3 'Vette (rather reassuringly he had a bare bbc block lying on the shop floor!) With everything adjusted to within spec. but steering still less than pin sharp, it seemed a good time to attempt a more comprehensive tuning of the box adjustment.

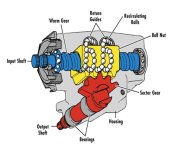

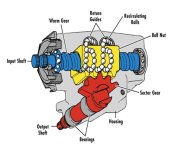

The Saginaw box has two adjustments to remove play. The obvious one is the screw on top of the box to adjust the mesh of the sector gear with the ball nut but there's another around the input shaft below the rag joint to remove end play in the wormshaft - this adjustment should be made first..

Ideally adjustment should be done with the box on the bench, or if left in the car at least with the Pitman arm disconnected. I elect to do neither. Being a power steering car the Pitman arm is connected directly to the control valve and separation often results in damage to the valve, however power steering does have one advantage in that until the engine is started and the valve pressurised, there is quite a lot of free play at the steering wheel which should make 'feeling' a tight spot easier.

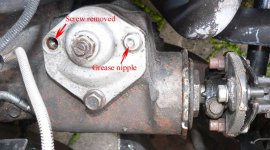

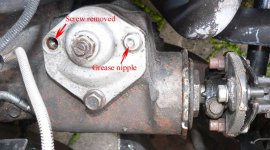

Box lubricant has probably not been refreshed since 1971 so first job is to load the box with grease. You can buy a

grease fitting specifically for the box for around £20 but it's easy to make your own. I found a 3/8" NC screw lying around the garage, shortened it, drilled it through and tapped it for a grease nipple ('zerk' to our colonial cousins).

Armed with this I assembled the tools for the job......

On the left left, grease, greasegun and 9/16" AF socket on a long extension bar to remove the box cover screws (If they haven't been moved in 50 years they're

tight ); in the middle a large flat bladed screwdriver and a short 5/8" AF ring spanner to adjust the gear mesh and on the right, a hammer and a long steel drift to loosen the wormshaft adjuster locknut and a short 1¾" wrench to do the adjustment. I removed two screws from the top of the box, refitted my greasing tool into one and injected copious amounts of grease.

Replaced original screws and then slackened off both adjusters. The lock nut on the wormshaft adjuster is slackened using the hammer and drift and then the adjuster wound out three or four turns using the wrench. Any lash in the wormshaft is taken up by torquing the adjuster to 5-8 lbf.in.. The arm on my wrench is about 6" so a force of about 1 lbf. applied to the end should do the trick. With the friction in the large thread on the adjuster this loading is not going to be very precise so I adjusted to remove any axial float and then gave the spanner a 'tweak'. Ensuring the adjuster didn't move I retightened the lock nut with the hammer and drift.

The sector gear lash is adjusted with the wheels straight ahead and the screw wound in until slight drag is felt at the steering wheel, then backed off about a ¼ turn. There is lost motion between the adjuster and the wormshaft so it's important to make the final adjustment by screwing the adjuster in. I did this by noting the adjuster position as the drag is felt, backing off a couple of turns, screwing in again 1 ¾ turns and then tightening the locknut while holding the screwdriver. With both adjustments done it's off for a test drive. There's certainly an improvement although the steering is still less than R&P sharp. I can though now travel down the road in a straight line without having to make constant minor corrections, so it's a significant gain.

I know there are improvements that can be made over the original system - Borgeson box or Steeroids R&P for example - but properly adjusted and maintained it's nice to keep originality.

Oh, and one final job, I put the 'Vette clock back one hour; any other C3 owners had to do the same?