I mentioned in another post on this that it is important to know what the CAM grind the engine has and esp

what the LSA is as that highly affects how the engine functions from startup to about mid RPMs

It of course effects how the car idles, cold, hot, A/C on or off and what type of tranny used

You can calculate the LSA using the centerlines of the intake and exhaust lobes

The formula for LSA is:

Intake Centerline + Exhaust Centerline ÷ 2

For example, if the intake is 107° and the exhaust is 117°:

107° + 117° = 224°

224° ÷ 2 = 112° (LSA)

How does it affect performance?

Combined with

Duration, the LSA determines

Valve Overlap. This overlap has a significant impact on

Engine Vacuum and idle quality.

- Camshafts with a "tight" LSA (106° - 109°) will usually have more overlap.

- Camshafts with a "wide" LSA (110° - 118°) will have less overlap.

Vacuum is the difference in air pressure between the inside of the intake manifold and the outside atmosphere.

The pressure difference creates suction and helps to draw air into the engine.

Engine vacuum is a required condition for a gasoline engine to run.

It helps control the engine rpm. Without proper vacuum, the engine won’t start. A vacuum leak can also cause high idle and run-away rpm.

How is it measured?

Vacuum is measured in inches of mercury (in. Hg).

An air pressure difference of 1 psi will move a column of mercury 2.036254 inches.

If your

Vacuum Gauge reads 20 in. Hg, the manifold pressure, is about 10 psi less than the atmospheric pressure.

What creates vacuum?

The engine creates vacuum under the following conditions:

- The piston is traveling down on the Intake Stroke.

- The intake valve is open.

- The exhaust valve is closed.

- The throttle blades are closed (or slightly open).

How does it affect performance?

Vacuum is actually a measurement of the engine’s inefficiency. Higher vacuum indicates that the engine is working harder to breathe.

This limits performance. However, it is necessary. Restricting the airflow and creating vacuum helps slow the engine down and limit rpm.

The vacuum created by the piston pulls air from outside, through the intake, into the cylinder. The throttle blades create restriction. This reduces the amount of air/fuel that goes into the cylinder. With less air/fuel, the engine cannot turn as fast.

As the throttle blades open, restriction and vacuum are reduced. This allows more air/fuel into the cylinder and rpm increases.

With the throttle wide open, airflow is maximized and vacuum is at its least.

When you let off the throttle and the blades snap shut, the RPM is still high. This creates a spike in vacuum.

The restriction starves the cylinder of air/fuel. The result is falling rpm and vehicle deceleration.

The table below lists vacuum ranges for most engines:

Engine Function | Vacuum Range |

Cranking | 3-5 in. Hg |

Idle | 14-20 in. Hg |

Cruising | 10-15 in. Hg |

Deceleration | 21-25 in. Hg |

Other vehicle systems also use engine vacuum. This can include:

- Brake Boosters

- Distributor Advance

- PCV Systems

- Etc.

In short, the more narrow the LSA is, the more loss of vacuum there will be, and you need to forget what stock GM settings are and make adjustments as to what the total makeup is to allow correct startup, and idle with all the conditions I mentioned above

If not knowing the CAM grind then at least measure to see what vacuum is at idle when engine is cold and hot

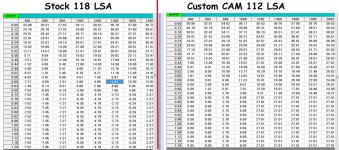

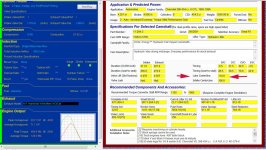

Example what I had to do to make up the loss of vacuum where stock LSA was 118 and with custom CAM where LSA was reduced to LSA

and had to change stock timing on left to changes I made on right to have proper startup and idle